Shurjoint Lubricant is recommended for proper gasket installation to prevent the gasket from being pinched. Apply a thin coat to the gasket exterior, gasket lips and/or housing interiors.

Shurjoint Lubricant is available in one pound (450 grams) and one quart (2 pounds or 900 grams) containers. Certified to NSF/ANSI 61.

.jpg)

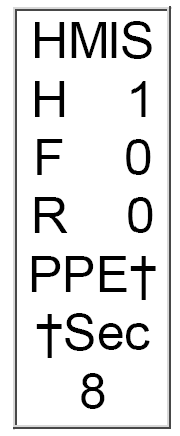

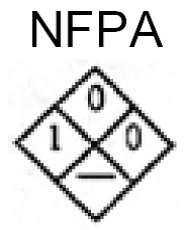

Material Safety Data Sheet

Section 1 — Chemical Product and Company Identification

Product /Chemical Name: SHURJOINT 550H PIPE JOINT LUBRICANT

Chemical Formula: 11-4

Shurjoint Piping Products USA,Inc

4703 Brill Street,Suite 32

Phoenix,AZ 85043

U.S.A

Emergency Phone #: 856-966-1526 Information Phone #: 702 644-4492

Manufacturer:

JTM Products, Inc.,

31025 Carter Street,

Solon, OH 44139

Section 2 — Composition / Information on Ingredients

Proprietary blend of non-hazardous ingredients

Section 3 — Hazards Identification

Section 3 — Hazards Identification

* * * Emergency Overview * * *

Potential Health Effects

Primary Entry Routes: Not hazardous

Carcinogenicity: IARC, NTP, and OSHA do not list the ingredients in Shurjoint 550H Water Dispersible Pipe Joint Lubricant as carcinogens.

Section 4 — First Aid Measures

Eye Contact: Flush with copious volumes of water for 15 minutes while holding eyelids open.

Skin Contact: Wash with water.

If irritation persists, call a physician.

Section 5 — Fire-Fighting Measures

Section 5 — Fire-Fighting Measures

Flash Point: >220°F (>104°C) LEL: NA

Flash Point Method: NA, contains water UEL: NA

Autoignition Temperature: NA

Flammability Classification: 0

Extinguishing Media: Water, water fog, alcohol foam, carbon dioxide or dry chemical are all suitable.

Unusual Fire or Explosion Hazards: None

Hazardous Combustion Products: None

Fire-Fighting Instructions: Do not release runoff from fire control methods to sewers or waterways.

Fire-Fighting Equipment: Because fire may produce toxic thermal decomposition products, wear a self-contained breathing apparatus (SCBA) with a full facepiece operated in pressure-demand or positive-pressure mode.

Section 6 — Accidental Release Measures

Spill/Leak Procedures: This product is a biodegradable soap.

Containment: For large spills, dike far ahead of spill for later disposal.

Cleanup: Place the bulk of any spilled material into drums, then rinse any remaining material to sewage treatment facility, in accordance with any applicable regulations.

Regulatory Requirements: Follow applicable OSHA regulations (29 CFR 1910.120).

Section 7 — Handling and Storage

Handling Precautions: No special precautions are required.

Storage Requirements: No special precautions are required.

Regulatory Requirements: No known regulatory requirements for handling and storage.

Section 8 — Exposure Controls / Personal Protection

Engineering Controls:

Ventilation: Provide general or local exhaust ventilation systems.

Administrative Controls:

Respiratory Protection: If respirators are used, OSHA requires a written respiratory protection program that includes at least: medical certification, training, fit-testing, periodic environmental monitoring, maintenance, inspection, cleaning, and convenient, sanitary storage areas.

Protective Clothing/Equipment: Wear chemically protective gloves to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eye- and face-protection regulations (29 CFR 1910.133). Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

Safety Stations: Make emergency eyewash stations, safety/quick-drench showers, and washing facilities available in work area.

Contaminated Equipment: Launder before reuse. Remove this material from your shoes and clean personal protective equipment.

Comments: Never eat, drink, or smoke in work areas. Practice good personal hygiene after using this material, especially before eating, drinking, smoking, using the toilet, or applying cosmetics.

Section 9 — Physical and Chemical Properties

Physical State: Paste

Appearance and Odor: off-white paste, bland odor

Odor Threshold: NA

Vapor Pressure: NA

Vapor Density (Air=1): NA

Formula Weight: NA (blend)

Density: 9.35 lbs./gal.

Specific Gravity (H2O)=1, at 4°C): 1.121

pH: (@5% solution)=8.95, >9.5 (neet)

Water Solubility: completely water dispersible

Boiling Point: >220°F

Freezing/Melting Point: <32°F

Viscosity: viscous paste

Refractive Index: unknown

% Volatile: ~33

Evaporation Rate: NA

Section 10 — Stability and Reactivity

Stability: Shurjoint 550H Water Dispersible Pipe Joint Lubricant is stable at room temperature in closed containers under normal storage and handling conditions.

Polymerization: Hazardous polymerization will not occur.

Chemical Incompatibilities:

Conditions to Avoid: Avoid contact with strong oxidizing agents.

Hazardous Decomposition Products: Thermal oxidative decomposition of Shurjoint 550H Water Dispersible Pipe Joint Lubricant can produce oxides of carbon and nitrogen.

Section 11 — Toxicological Information

Toxicity Data:

Eye Effects: Eye irritant [based on blended ingredients]

Skin Effects: Slight skin irritant if allowed to remain in contact.

Section 12 — Ecological Information

Ecotoxicity:

Environmental Fate:

Environmental Transport: Unknown.

Environmental Degradation: Soaps are well known to be biodegradable.

Soil Absorption/Mobility: Unknown.

Section 13 — Disposal Considerations

Disposal: Contact your supplier or a licensed contractor for detailed recommendations. Follow applicable Federal, State, and local regulations.

Section 14 — Transport Information

Not hazardous under DOT regulations.

Section 15 — Regulatory Information

EPA Regulations:

OSHA... None; TSCA … All ingredients appear on inventory;

CERCLA Section 102 (reportable quantity RQ) 40CFR 302; SARA: not applicable;

CLEAN WATER ACT …. Contains Sodium Hydroxide, section 311 material

INTERNATIONAL REGULATIONS... None

CANADIAN ENVIRONMENTAL PROTECTION ACT (CEPA) …… none

The above information and recommendations are believed to be accurate and reliable. However, no warranties, either expressed or implied with respect to the product or information herein are made. Users must make their own determination as to the suitability of the product for their purposes prior to use.