Proper gasket selection is essential for the optimum performance of Shurjoint grooved couplings, flange adapters and mechanical tees.

1. Gasket styles: Shurjoint grooved couplings utilize several different gasket styles, standard, GapSeal, EP (End Protection) and FF (Fast Fit). GapSeal gaskets are compatible with standard gaskets and they are interchangeable with each other. Other special styles are not compatible with standard or GapSeal gaskets. Always use the correct gasket style for the coupling model you selected.

.jpg)

2. Vacuum service: Shurjoint standard gaskets are designed to seal well under vacuum conditions up to 10 inHg (absolute)/254 mmHg (absolute) which may occur when a system is drained. For continuous services greater than 10 inHg (absolute)/254 mmHg (absolute), the use of GapSeal gaskets or EP (end protection) gaskets in combination with rigid style couplings is recommended. Contact Shurjoint for specific recommendations.

3. Dry pipe and freezer services: Shurjoint recommends the use of GapSeal Grade "E" gaskets for dry pipe fire protection systems and freezer applications. The GapSeal gasket closes off the gap between the pipes or gasket cavity. This will prevent any remaining liquid from entering the cavities and freezing when the temperature drops. Rigid couplings are preferred for dry pipe, freezer and vacuum applications. Reducing couplings are not recommended for these applications.

Note: Do not use the Shurjoint standard Lubricant for dry pipe and freezer systems, instead use a petroleum free silicone based lubricant.

4. NSF/ANSI 61 Standard: NSF/ANSI 61 classified gaskets are good for potable water services. The classification categories are "cold" which is limited to +86°F (+30°C) (or maximum ambient distribution temperatures of unheated water) maximum and "hot" which is limited to +180°F (+82°C) (or scalding temperatures of hot domestic water).

5. NSF/ANSI 372 Standard: Maximum Lead Content (formerly Annex G): Product complies with NSF/ANSI 372 and conforms with lead content requirements for “lead free” plumbing as defined by California, Vermont, Maryland and Louisiana State laws and the U.S. Safe Drinking Water Act in effect as of Jan. 4, 2014.

.png) 6. Lubricant: Shurjoint Lubricant is recommended for proper gasket installation to prevent the gasket from being pinched. Apply a thin coat to the gasket exterior, gasket lips and/or housing interiors. Shurjoint Lubricant is available in one pound (450 grams) and one quart ( 2 pounds or 900 grams) containers. Certified to NSF/ANSI 61.

6. Lubricant: Shurjoint Lubricant is recommended for proper gasket installation to prevent the gasket from being pinched. Apply a thin coat to the gasket exterior, gasket lips and/or housing interiors. Shurjoint Lubricant is available in one pound (450 grams) and one quart ( 2 pounds or 900 grams) containers. Certified to NSF/ANSI 61.

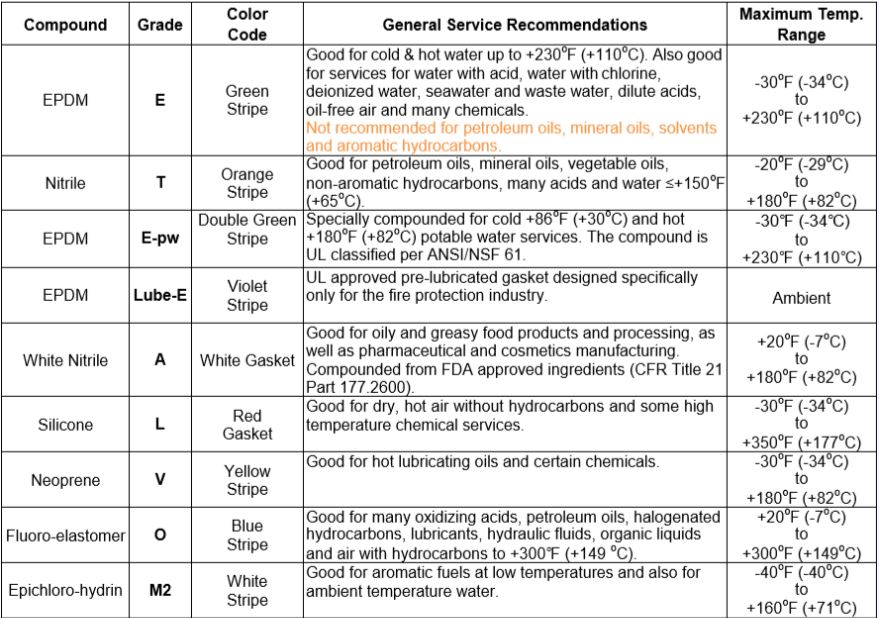

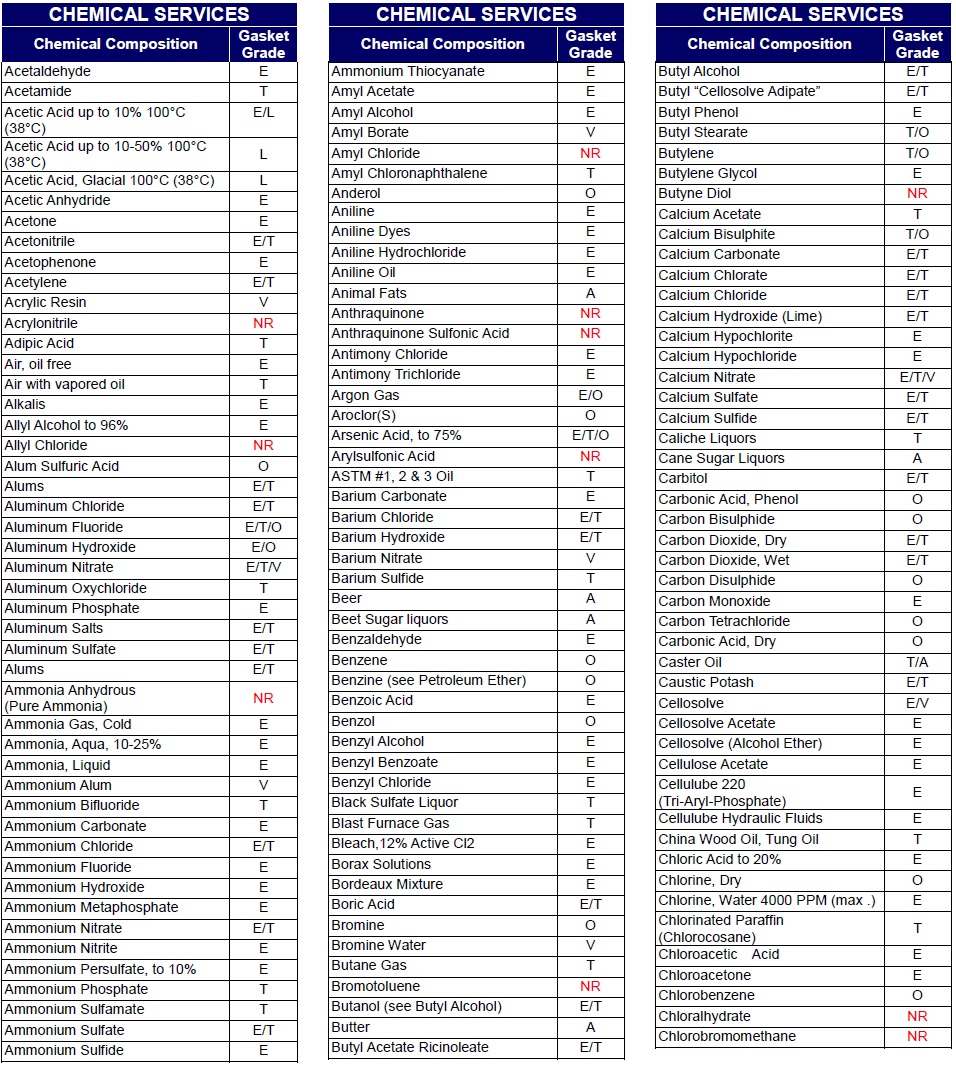

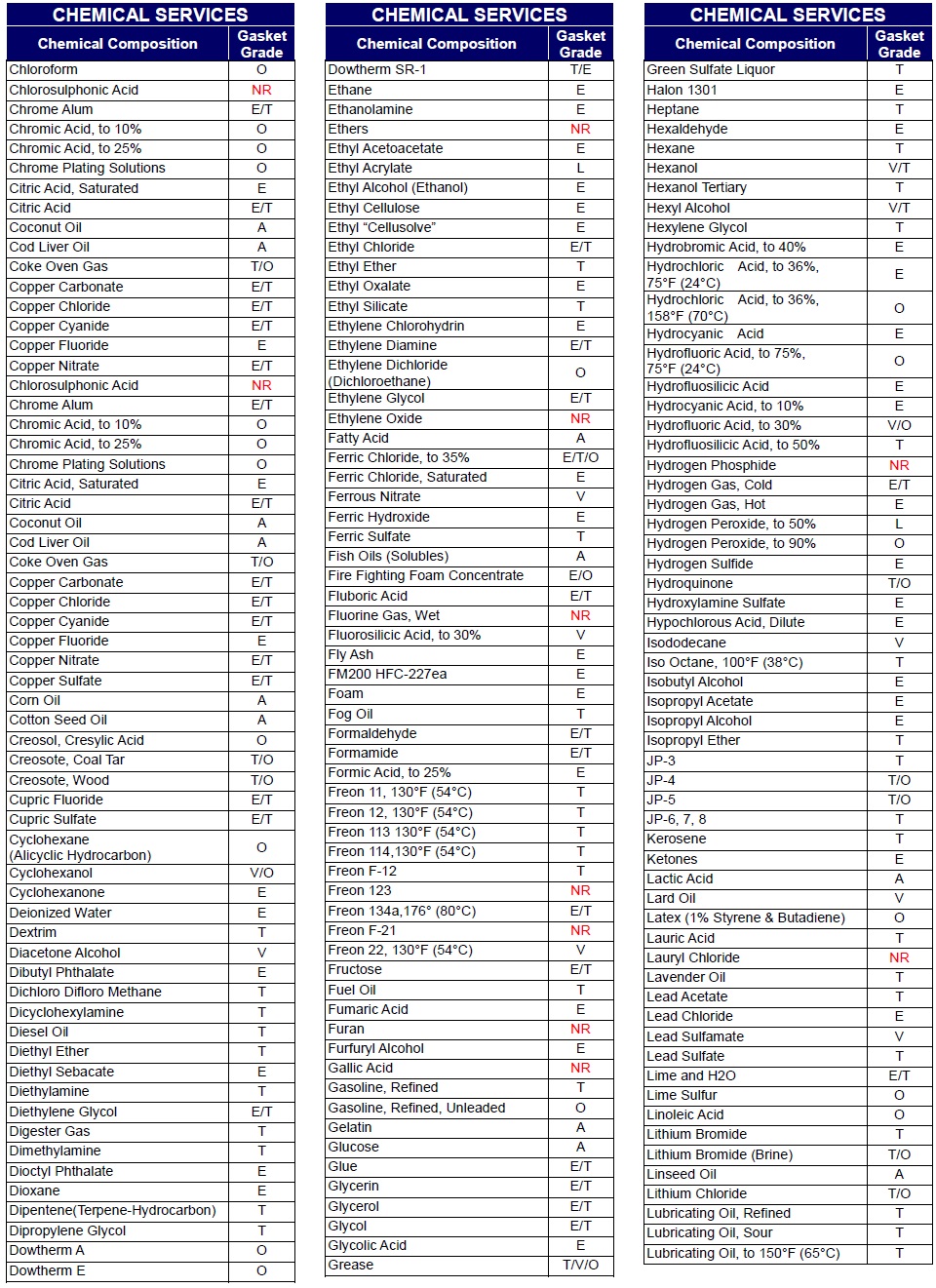

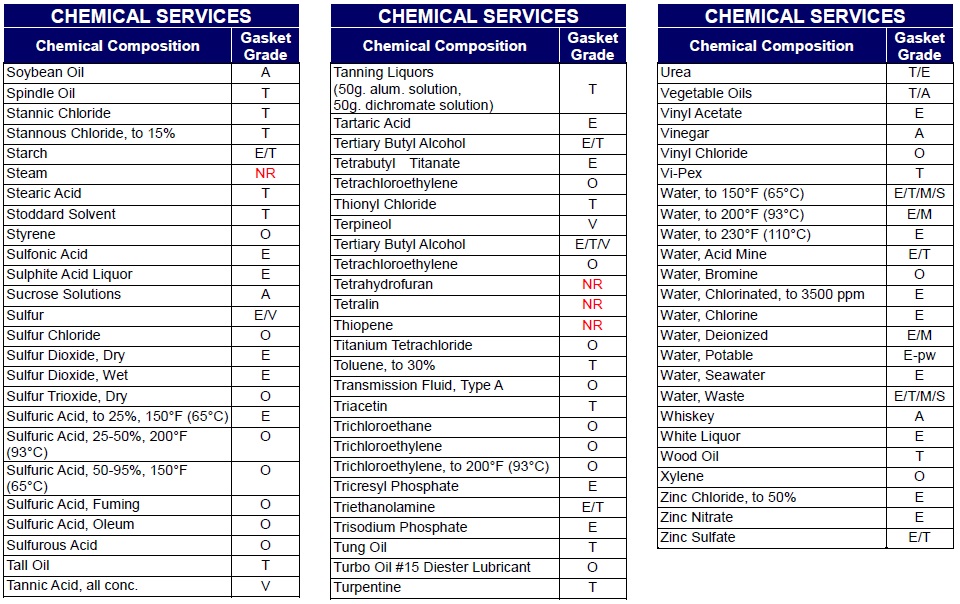

GASKET GRADE INDEX

Special Gaskets for AWWA Ductile Iron Pipe

(1).jpg) WARNING !

WARNING !

EPDM gaskets for water services are not recommended for steam services.

Failure to select the proper gasket and compound may result in joint leakage or failure resulting in personal injury and/or property damage. Gaskets should never be exposed to temperatures outside their ratings.

GENERAL GASKET SERVICE RECOMMENDATIONS

The following are general service recommendations only and the information provided is based on the best information available from various resources including elastomer manufacturers, leading rubber molders, industry publications and our own laboratory testing and field experience. The information contained herein shall be considered for evaluation purposes and not as a guarantee. When and wherever possible, gasket materials should be tested with simulated service conditions to determine suitability for the intended service application. Unless otherwise noted, the recommendations are based on ambient temperatures. These recommendations do not apply to rubber lined products or rubber sealed valves. If more than one gasket grade is listed the preferred grade is listed first for general services. For chemicals not listed, a combination of chemicals listed or not, service temperatures not listed or borderline services, contact a Shurjoint Engineering Representative for a recommendation. Note: NR = Not Recommended

(3).jpg)

WARNING !

Gaskets should never be exposed to temperatures outside their ratings. EPDM gaskets for water services are not compatible for steam services. Failure to select the proper gasket and compound may result in joint leakage or failure resulting in personal injury and/or property damage. For more details and support, please contact Shurjoint.