Materials

Ductile Iron - Housing

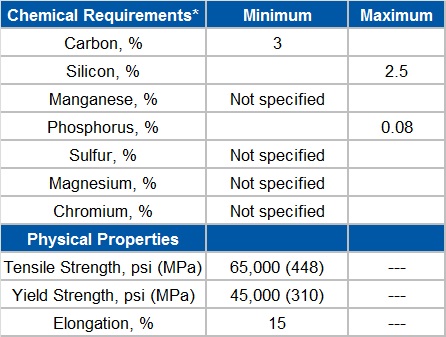

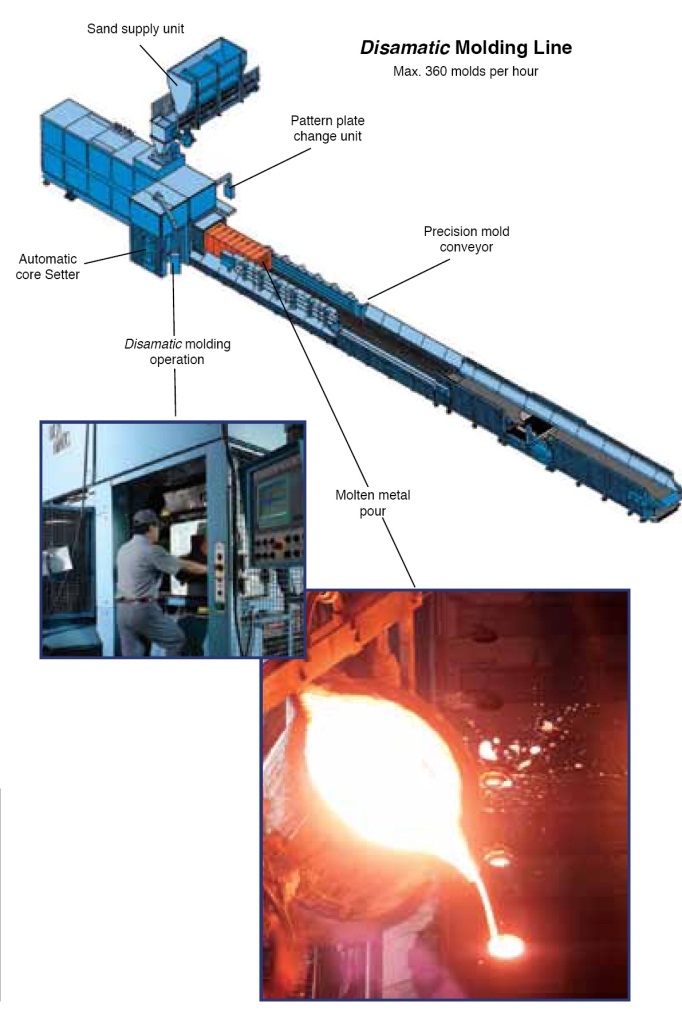

Ductile iron is an ideal material for grooved mechanical components, as it provides similar or greater strength to that of wrought or cast steel piping materials such as; forged steel flanges - ASTM A105, carbon steel valves - ASTM A216 WCB, wrought carbon steel pipe - ASTM A53 Gr. B, etc. Most Shurjoint components are made of ductile iron conforming to ASTM A536 Gr. 65-45-12 and or ASTM A395 Gr. 65-45-15.

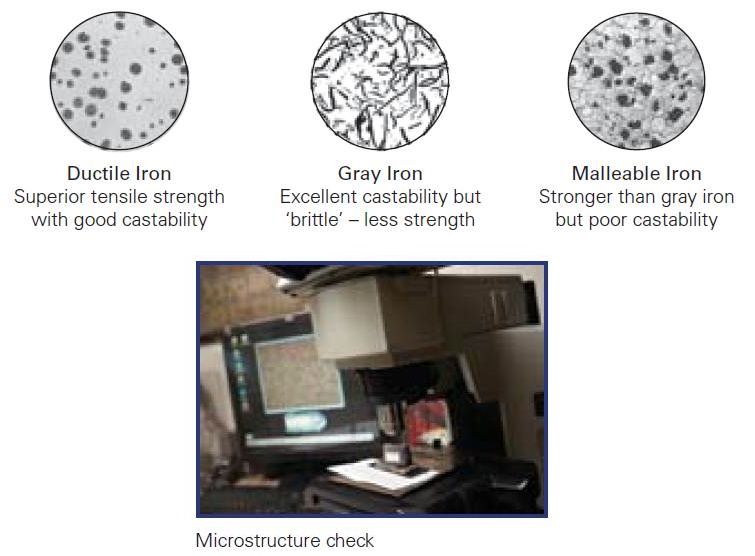

Ductile iron was first invented in the U.S.A. and U.K. in the late 1940's. Superior strength was achieved by crystallizing graphite in the shape of nodules. The result was ductile iron that had tensile and yield strength properties that were equal to or greater than some steel castings. This superior strength combined with ductile irons excellent castability helped to reduce the weight and cost of many components. Because of these advantages and benefits, many components have been converted from gray iron, malleable iron and steel castings to ductile iron over the past 60 years. Please visit the Ductile Iron Society website; www.ductile.org, for further information.

International ductile iron specifications equivalent to ASTM A536 Gr. 65-45-12 and or ASTM A395 Gr. 65-45-15 are;

SAE J434: D4512

EN1563: EN-GJS-450-10 or EN-GJS-450-15

JIS G5502: FCD450-10

SABS 936/937: SG42

Physical strength of materials comparative

.jpg)

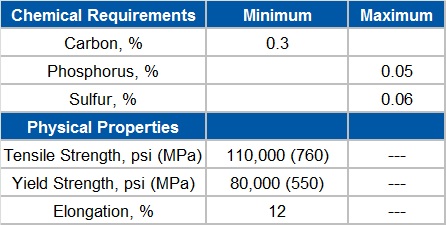

ASTM A536, Grade 65-45-12 (UNS F33100)

.jpg)

*Reference only as chemical requirements are not specified in ASTM A536

ASTM A395, Grade 65-45-15 (UNS F33100)

Bolts & Nuts

Carbon steel bolts and nuts

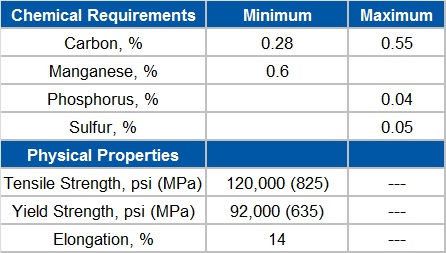

Shurjoint products utilize oval neck track bolts conforming to ASTM A449 or ASTM A183 Gr. 2 and heavy duty nuts to ASTM A563 Gr. B, available with UNC threads or ISO metric threads. The UNC track bolts and nuts are supplied electro zinc plated in a silver chromate color and ISO metric bolts and nuts in a gold chromate color. Hot-dip galvanized bolts and nuts are also available upon request.

ASTM A449, Quenched and Tempered Steel Bolts*

*Equivalent to property class 8.8 bolts per ISO 898

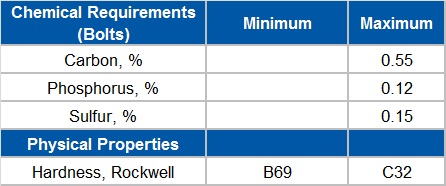

ASTM A183, Grade 2 Carbon Steel Track Bolts

ASTM A563, Grade B Carbon and Alloy Steel Heavy Hex Nuts

Stainless steel bolts and nuts

Stainless steel track bolts and nuts, type 304 or type 316, are supplied with Shurjoint stainless steel couplings. Track bolts and nuts are molybdenum disulfide (MoS2) coated to inhibit galling. As an option, silicon bronze nuts are also available to further reduce the chance of galling.

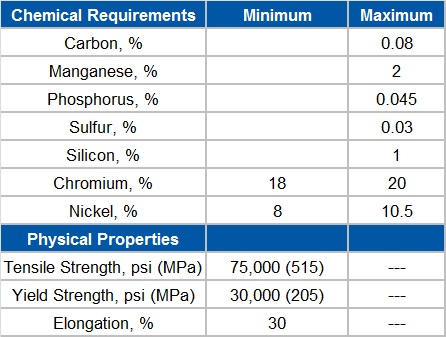

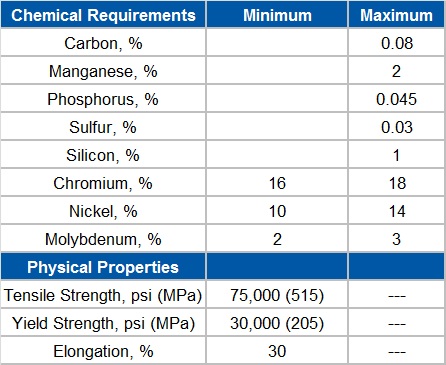

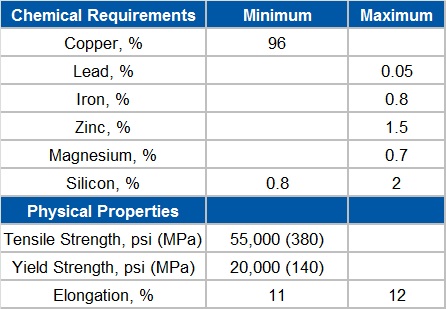

ASTM A193, Grade 8 (Type 304) Stainless Steel Bolts

ASTM A193, Grade B8M (Type 316) Stainless Steel Bolts

Silicon Bronze Nuts

ASTM B98 Alloy B Copper-Silicon Alloy (UNS No. C65100)

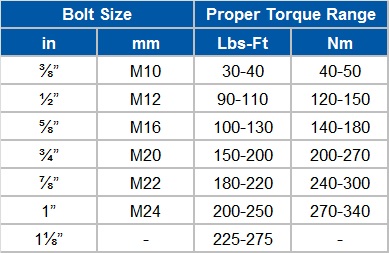

Recommended Bolt Torque

Always use factory supplied bolts and nuts for assembly of Shurjoint couplings. Shown below are the general recommended torque ranges for common sizes of carbon steel bolts. Never exceed the recommended torque range by more than 25% as excessive torque can lead to joint failure, personal injury and or property damage.

Always depressurize and drain the piping system before attempting disassembly, adjustment or removal of any piping component. Follow installation instructions for proper assembly of all Shurjoint components. For questions contact Shurjoint.

For stainless steel bolts, reduce by 20%

Rubber Gasket Compounds

The 20th century was the era of innovation in plastic and rubber materials. Among the new synthetic rubber compounds that most impacted our industry were EPDM (ethylene propylene diene monomer) and Nitrile rubbers.

Please refer to the Gasket Selection Guide (Shurjoint cut sheet #B-03) for additional information relating to service temperatures and chemical resistance.

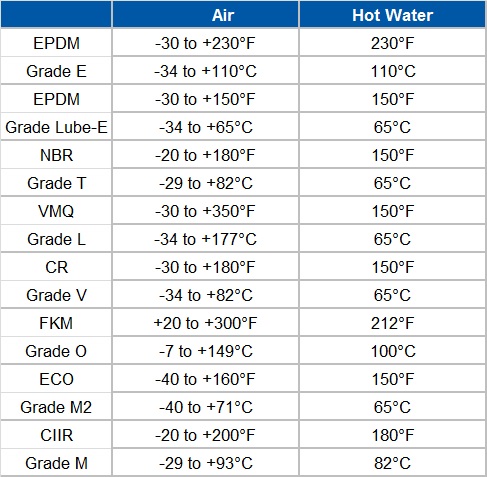

EPDM is recognized as the most water resistant rubber available today. Good for cold & hot water up to 250ºF (121ºC), waste water, water with acid, deionized water and seawater. EPDM is not recommended for use with petroleum based oils and fuels,

hydrocarbon solvents and aromatic hydrocarbons.

Shurjoint Grade "E" EPDM is compounded per ASTM D2000 designation 2CA615A25B24F17Z. Peroxide curing and post curing give a higher crosslink density, which provides a higher aging resistance than required in AWWA C606.

.jpg)

Use Shurjoint Grade "E-pw" for potable water and food processing services. The Grade "E-pw" is UL classified per ANSI/NSF 61 for cold +86°F (30°C) and hot +180°F (82°C) potable water services. EPDM seals are recommended for use in breweries as they have the least impact on the characteristics of beer or wort.

Note: EPDM materials used in domestic water applications with high levels of chlorine and or chloramines should be subjected to resistance testing, as not all materials will be suitable. EPDM materials with higher saturated ethylene content and lower carbon black content are recommended for chloramine and chlorine resistance. Contact Shurjoint for further information.

NBR, Buna-N, and Nitrile all represent the same copolymer of butadiene and acrylonitrile (ACN), which is inherently resistant to hydraulic fluids, lubricating oils, transmission fluids and other non-polar petroleum based products and water less than 150º F (65º C). The higher the ACN content, the higher the resistance to oils and heat, but the lower elastic characteristics and compression set. NBR displays poor resistance to hot water and steam.

Shurjoint grade “T” NBR rubber is compounded based on ASTM D2000 designation 5BG615A14B24Z and exceeds the requirements of AWWA C606. Grade “T” is a general purpose compound with a medium ACN level. For fuels, especially those with a low aniline point, such as premium or unleaded gasoline, ASTM referenced fuels B & C and naphtha, use Shurjoint grade “M2” Epichloro-Hydrin or grade “O” Flurocarbon.

.jpg)

Use Shurjoint Grade "A" white Nitrile gaskets for oily and greasy food products and processing, as well as pharmaceutical and cosmetics manufacturing. The Grade "A" is compounded from FDA approved ingredients (CFR Title 21 Part 177.2600).

Use Shurjoint Grade "S" Nitrile gaskets for joints with AWWA ductile iron pipe. Good for mineral oils, vegetable oils, air with oil vapors and water less than 150°F (65°C).

Silicone (VMQ) Shurjoint Grade "L" Silicone compound features high temperature range stability and low temperature flexibility. Recommended for dry heat and air without hydrocarbons up to 350º F (177º C). Silicone compounds are used in many food and medical applications as they do not impart odor or taste. Not recommended for hot water or steam services.

Silicone (VMQ) Shurjoint Grade "L" Silicone compound features high temperature range stability and low temperature flexibility. Recommended for dry heat and air without hydrocarbons up to 350º F (177º C). Silicone compounds are used in many food and medical applications as they do not impart odor or taste. Not recommended for hot water or steam services.

Chloroprene (CR, Neoprene) Shurjoint Grade "V" chloroprene rubber is a general purpose elastomer that demonstrates good resistance to lubricating oils, animal & vegetable fats and greases. Chloroprene is not effective in aromatic and oxygenated solvent environments and is not recommended for hot water and steam services.

Chloroprene (CR, Neoprene) Shurjoint Grade "V" chloroprene rubber is a general purpose elastomer that demonstrates good resistance to lubricating oils, animal & vegetable fats and greases. Chloroprene is not effective in aromatic and oxygenated solvent environments and is not recommended for hot water and steam services.

Fluorocarbon (FKM) FKM is a highly fluorinated carbon backboned compound and offers excellent resistance to harsh chemical and ozone attack with a thermal stability to 300°F (149°C). Shurjoint Grade "O" fluorocarbon gasket is recommended for use with oils, gasoline, hydraulic fluids, hydrocarbon solvents and extended fuels that fall outside the service parameters of grade T / NBR compounds. Not recommended for steam services.

Fluorocarbon (FKM) FKM is a highly fluorinated carbon backboned compound and offers excellent resistance to harsh chemical and ozone attack with a thermal stability to 300°F (149°C). Shurjoint Grade "O" fluorocarbon gasket is recommended for use with oils, gasoline, hydraulic fluids, hydrocarbon solvents and extended fuels that fall outside the service parameters of grade T / NBR compounds. Not recommended for steam services.

Epichloro-Hydrin (ECO) Shurjoint Grade "M2" compound offers good to excellent resistance to aliphatic hydrocarbon and aromatic hydrocarbon fuels at low temperatures, LP gases & fuels, mineral oils and many solvents. ECO offers limited resistance to many organic chemicals.

Epichloro-Hydrin (ECO) Shurjoint Grade "M2" compound offers good to excellent resistance to aliphatic hydrocarbon and aromatic hydrocarbon fuels at low temperatures, LP gases & fuels, mineral oils and many solvents. ECO offers limited resistance to many organic chemicals.

Halogenated Butyl (CIIR) Shurjoint Grade "M" CIIR is specially compounded for use with AWWA ductile iron pipe for water services, mild dilute acids, oil-free air and many chemicals. The compound is UL classified for potable water use per ANSI/NSF 61.

Halogenated Butyl (CIIR) Shurjoint Grade "M" CIIR is specially compounded for use with AWWA ductile iron pipe for water services, mild dilute acids, oil-free air and many chemicals. The compound is UL classified for potable water use per ANSI/NSF 61.

Service temperatures The following chart can serve as a general guide for temperature and media compatibility for Shurjoint gaskets. The range shown below is only a guide and users should always test the gasket materials for the specific operating and service application, as conditions can vary.

*EPDM gaskets for water services are not recommended for steam services unless coupling or components are accessible for frequent gasket replacement.