ANCHORING, HANGING AND SUPPORTS

Shurjoint grooved couplings are designed to hold axial thrusts 4–5 times their rated working pressure, though the strength against bending movements is less than that of steel pipe. The joint may be damaged when a bending movement greater than the allowed deflection occurs. System designers should provide anchors (main and intermediate) and pipe guides with proper spacing to protect the system from unexpected large bending movements.

These illustrations are examples only, and are not intended to be used for all installations as conditions and requirements vary from job to job. Reliance on general data or information contained herein shall be at the user's sole risk and without obligation to Shurjoint.

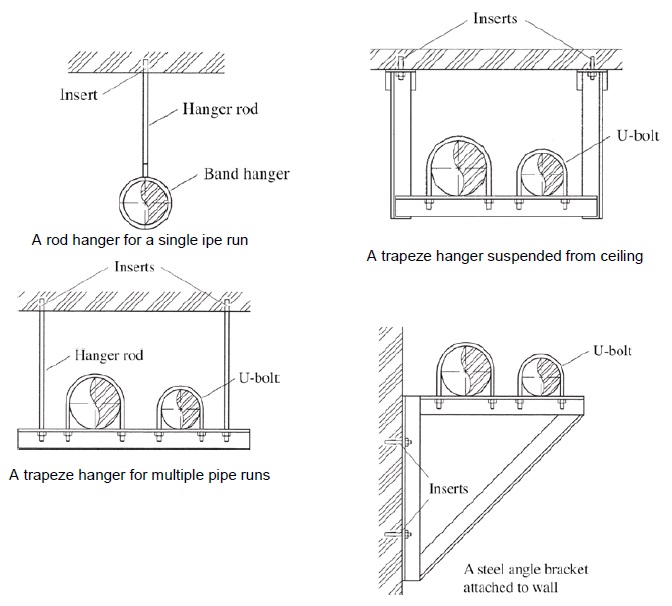

Hangers shall be designed to support five times the weight of water-filled pipe plus 250 lb (115 kgs) at each point of pipe support (NFPA 13 9.1.1.1.). The following illustrations are examples of acceptable hanger types and sizes per NFPA 13.

.jpg)

Hangers for straight runs

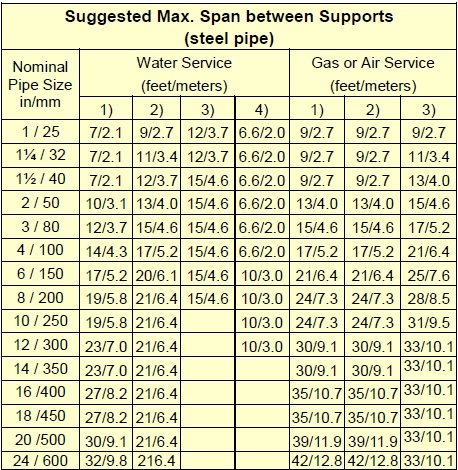

For straight runs, you can use both flexible and rigid couplings. When rigid couplings are used, the same hanger spacing as other piping methods can be applied. You can refer to the hanger spacing standards of ANSI B31.1 Power Piping Code, B31.9 Building Services Piping Code, NFPA 13 Sprinkler Systems, or Mechanical Equipment Construction Guide (Japan). See the table below.

1) ANSI B31.1 Power Piping Code

2) ANSI B31.9 Building Services Piping Code

3) NFPA 13 Sprinkler systems

4) Ministry of Land & Transportation of Japan: Mechanical Equipment Construction Guide

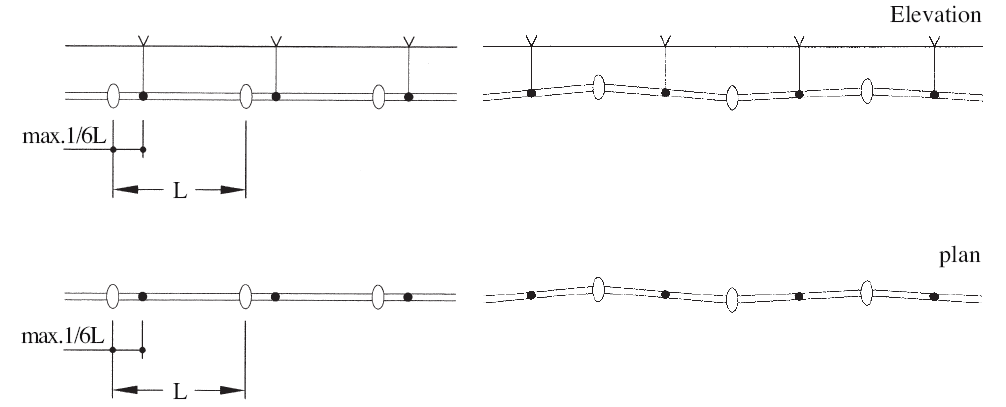

Hanger locations on straight runs where flexible couplings are used

When flexible couplings are used on straight runs, location of hangers shall be designed as close to each coupling as possible, or within a distance of less than 1/6 the span.

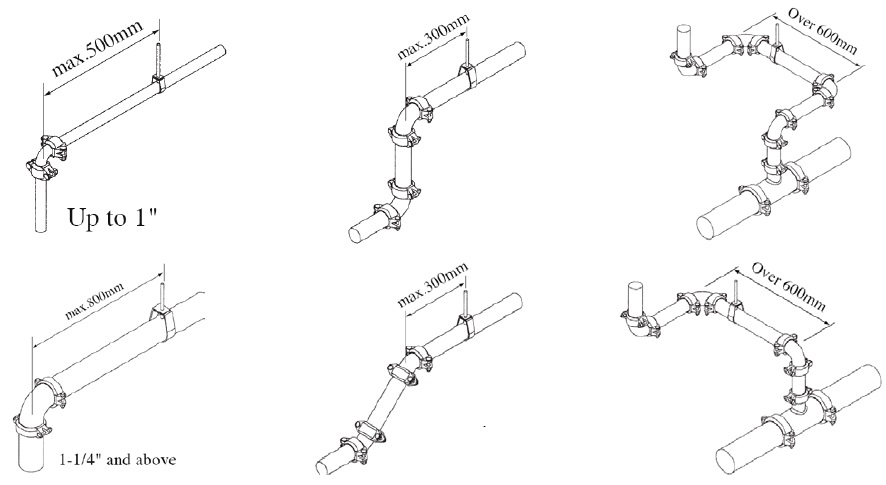

Hanger locations on curved pipe runs and branch lines

Additional hangers or supports shall be provided where Runs are curved, connected to a branch line or on short risers or drops

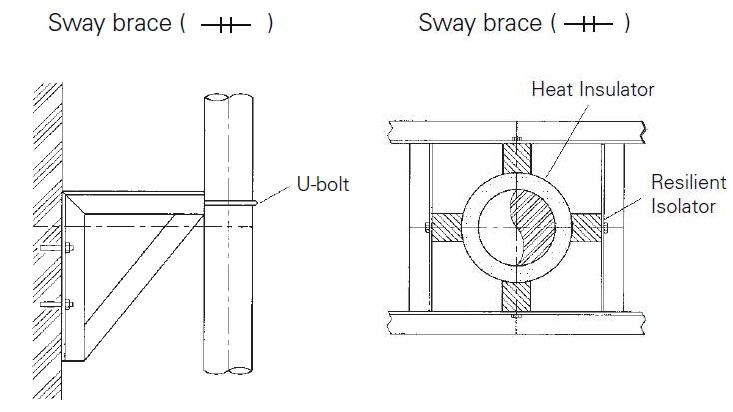

Typical designs of hangers and sway braces for pipe runs

Pipe runs shall be adequately suspended by rod hangers or steel angles that are directly attached to the building structure to restrict the movement of the piping. Hangers and their components shall be ferrous. The maximum distance between hangers shall not exceed that specified in the table of previous page.

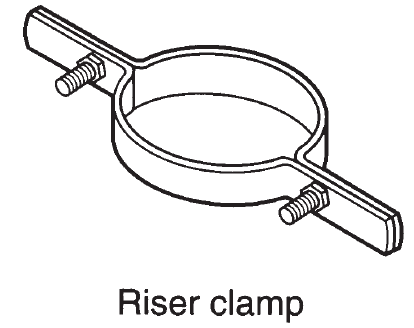

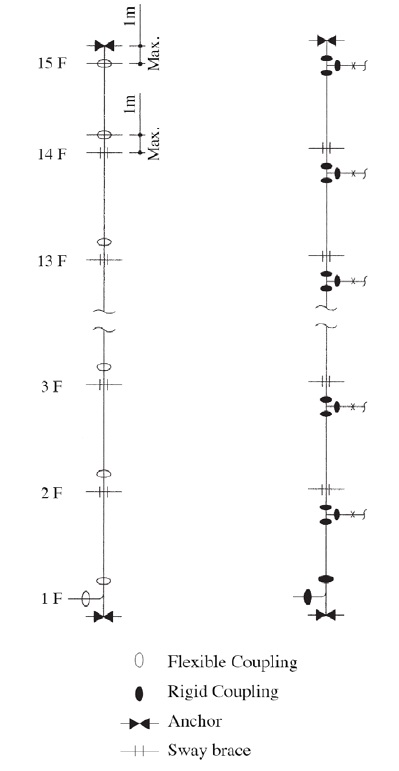

Supports for risers

In multi-story buildings, risers shall be fixed (or anchored) at the lowest level and at the top of the riser and shall be supported by riser clamps or U-bolts at each floor level to prevent the risers from swaying. If risers are braced by the penetration floors, the number of riser clamps or U bolts may be reduced to one at each three stories. For risers, either flexible or rigid couplings can be used as long as proper anchoring and support is provided.

In multi-story buildings, risers shall be fixed (or anchored) at the lowest level and at the top of the riser and shall be supported by riser clamps or U-bolts at each floor level to prevent the risers from swaying. If risers are braced by the penetration floors, the number of riser clamps or U bolts may be reduced to one at each three stories. For risers, either flexible or rigid couplings can be used as long as proper anchoring and support is provided.

- Anchors should be sufficient to hold the weight of waterfilled pipe and pressure thrusts.

- Pipe guides (sway braces) should be such as to brace lateral movement of the system.