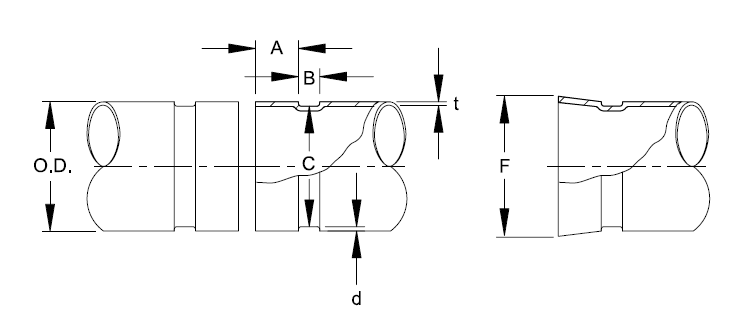

Standard Roll Groove Dimensions for U.S. Standard Copper Tubing

.jpg)

Pipe O.D. (Column 2):

Maximum allowable tolerances from square cut ends is 0.03" for 2" thru 3"; 0.045" for 4" thru 6"; and 0.060" for sizes 8”.

Gasket Seating Surface (Column 3):

The gasket seating surface shall be free from deep scores, marks, or ridges that would prevent a positive seal.

Groove Width (Column 4):

Groove width is to be measured between vertical flanks of the groove side walls.

Groove Diameter (Column 5):

The “C” diameters are average values. The groove must be of uniform depth around the entire pipe circumference.

Groove Depth (Column 6):

The “d” is for reference use only. The groove dimension shall be determined by the groove diameter “C”.

Minimum Wall Thickness (Column 7):

The DWV pipe (ASTM B-306) is minimum wall thickness that may be roll grooved.

Flare Diameter (Column 8):

The pipe end that may flare when the groove is rolled shall be within this limit when measured at the extreme end of the pipe.

Standard Roll Groove Dimensions for British Standard Copper Tubing

.jpg) Pipe O.D. (Column 1):

Pipe O.D. (Column 1):

Maximum allowable tolerances from square cut ends is 0.03" for 2" thru 3"; 0.045" for 4" thru 6"; and 0.060" for sizes 8”.

Gasket Seating Surface (Column 2):

The gasket seating surface shall be free from deep scores, marks, or ridges that would prevent a positive seal.

Groove Width (Column 3):

Groove width is to be measured between vertical flanks of the groove side walls.

Groove Diameter (Column 4):

The “C” diameters are average values. The groove must be of uniform depth around the entire pipe circumference.

Groove Depth (Column 5):

The “d” is for reference use only. The groove dimension shall be determined by the groove diameter “C”.

Flare Diameter (Column 6):

The pipe end that may flare when the groove is rolled shall be within this limit when measured at the extreme end of the pipe.