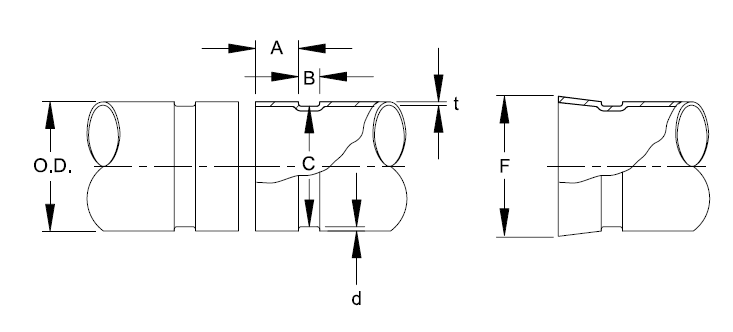

STANDARD ROLL GROOVE FOR LARGE DIAMETER IPS PIPE

.jpg) Nominal Pipe Size (Column 1):

Nominal Pipe Size (Column 1):

Nominal pipe size, IPS pipe to ANSI B36.10 and ISO 4200.

Pipe OD (Column 2):

Maximum allowable tolerances from square cut are 0.060” (1.6mm).

Gasket Seating Surface (Column 3):

The gasket seating surface ‘A’ shall be free from deep scores, marks, or ridges that would prevent a positive seal.

Groove Width (Column 4):

Groove width is to be measured between vertical flanks of the groove side walls.

Groove Diameter (Column 5):

The ‘C’ dimensions are average values. The groove must be of uniform depth around the entire circumference. Use a Shurjoint groove or rule to check the groove

diameter.

Groove Depth (Column 6):

The ‘d’ is for reference use only. The groove depth shall be determined by the groove diameter ‘C’.

Minimum Wall Thickness (Column 7):

The ‘t’ is the minimum allowable wall thickness that may be roll-grooved.

Flare Diameter (Column 8):

The pipe end that may flare when the groove is rolled shall be within this limit when measured at the extreme end of the pipe.